Manufacturing

Regardless of your manufacturing environment - whether make-to-stock, make-to-order, or mixed mode - the flexibility of the AddonSoftware Manufacturing system makes it a very practical solution. The system provides for precise tracking of work in process, streamlined scheduling, and manufacturing costs. The system includes Bill of Materials and Shop Floor Control with scheduling.

The AddonSoftware Manufacturing System is for manufacturing companies of durable goods with annual sales from about $3 million to $30 million. The system is primarily Work Order driven, and efficiently tracks the movement of work orders through the manufacturing process. A work order may be created from a bill of materials, from a historical work order, a work order "template," or from scratch, depending on the need. A work order may be issued for a standard item, a custom product, or for a recurring need such as plant maintenance, with costs tracked properly and closed out either at standard or actual.

The system provides for multiple warehouses, with costs, prices, buying, replenishment, and item history by warehouse. It also includes complete lot/serial number tracking throughout the manufacturing and distribution process. One of the more popular features is that reports, sales invoices, customer statements, vendor POs, and other output can be sent via e-mail or fax, or output in HTML or Adobe® PDF format at any time.

The system provides for multiple warehouses, with costs, prices, buying, replenishment, and item history by warehouse. It also includes complete lot/serial number tracking throughout the manufacturing and distribution process. One of the more popular features is that reports, sales invoices, customer statements, vendor POs, and other output can be sent via e-mail or fax, or output in HTML or Adobe® PDF format at any time.

AddonSoftware for Manufacturers applications are feature-rich, mature, and proven. The system is comprised of the following applications:

- Bill of Materials

- Shop Floor Control

AddonSoftware for Manufacturers fully integrates with General Accounting and Distribution bundles which are required.

Bill of Materials

The AddonSoftware Bill of Materials application is a dynamic, convenient system designed for companies that assemble finished goods and manufacture some or all of the components. It provides unlimited levels of material usage and has features that easily define and track material, labor, subcontract, and overhead costs. Manufacturing cost accuracy is one of the system’s primary strengths. Built-in flexibility allows you to define your materials in any unit of measure, and adjusting factors for scrap and yield make material requirements easy to define yet accurate to great precision.

Routings, with labor operations and subcontract steps, may be defined for each BOM. Message lines are provideed so that companies can include manufacturing instructions for materials, labor operations, and subcontract steps in detail. Messages for materials are printed on pick lists, operation instructions are printed on the Work Order Traveler, and subcontract messages can be printed on purchase order lines.

Engineering change orders may be entered in advance of the change with effective dates. Full change order history is available through the use of a production date, and you’ll be able to create complete reports showing only the current requirements or a full history of all change orders. Effective and obsolete dates are available for materials, labor operations, subcontract steps, and even instruction (message) lines. Roll up costs on demand, either globally or selectively. Environments without work orders can quickly backflush components after manufacturing for single-step inventory updating.

- Easy BOM creation and copy function

- Phantom BOMs for common groups of items

- Scrap factor and yield percents for accurate material tracking

- User-defined Operation Codes for routings and scheduling

- Setup, Run, Queue, and Move times for tighter scheduling

- Where-used reports for materials and operations

- Global component replacement program

- Fast production entry and backflushing

- Component Availability Inquiry for determining Available to Promise

Shop Floor Control

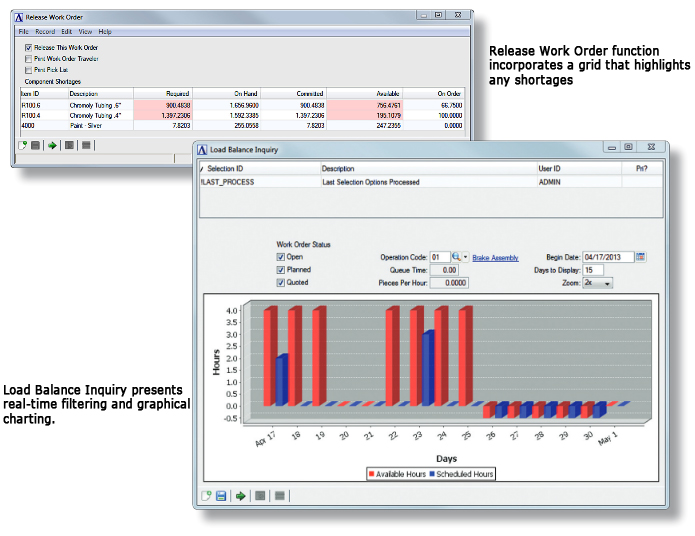

The purpose of AddonSoftware Shop Floor Control is to help you define, schedule, and manage your production floor in the most efficient way possible. Automatically or manually schedule each work order, either forward from its start date or backward from the completion date. Use the MRP system to automatically generate planned work orders for more efficient manufacturing. You can plan work center activity with the Load Balance display and the Dispatch Display or Inquiry.

Shop Floor Calendars for each work center are provided to assist in planning and scheduling. The calendar sets the available hours for each center, with holidays and days off defined, making it easier for you to maintain schedules. Get control of work in process through complete tracking of work orders as they move through the shop floor. Stock and Non-Stock type work orders allow the manufacture of repetitive items and "same as except for" jobs.

Custom work orders may be easily managed by duplicating a work order "template," a work order from history, or by modifying an existing similar bill of materials. Start with a Work Order Quote to help determine your expected manufacturing costs, and convert to a Planned or Released Work Order with a single keystroke.

Use work order history to compare your standard costs and lead times to actuals. Report variances by work order, operations, materials, and subcontract steps from the system’s extensive cost accounting procedures. Use the Labor Cost Analysis Report to monitor efficiency and utilization factors.

- Track planned and quoted work orders

- Tie Work Order to Sales Order line item for accurate tracking and posting of cost to sales invoice

- Extensive variance tracking and reporting

- Automatic purchase order generation for subcontracted steps

- Shop floor dispatch report

- On-line inquiry of "on order" status for open work orders

- Lots or serial numbers can be issued or created with complete audit trails

- On-line work order information is always available for you to review the current status of each operation or job

- Automatically generate purchase orders for subcontracted services